Since 1988, the ControLogic™ system has evolved from an ultra-fast precise motion control system to an Intelligent control system for microbiological processes. As a control philosophy, ControLogic™ is based on algorithms developed over the years by the Osorno Automation Team. The hardware currently preferred in the ControLogic™ Intelligent control system is the WAGO 750 system; WAGO recognizes Osorno as a Systems Provider and Integrator with special expertise in the water and wastewater field.

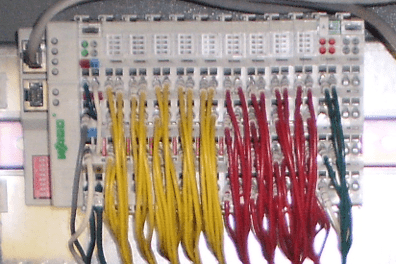

The picture (left) shows the ControLogic™ system for the automation of a wastewater treatment plant at a nursing station in Red Sucker Lake First Nation, Canada. Notice how compact a PLC system can be; this is because of WAGO’s “blade” modules.

Each of the modules shown in the picture is for 8 digital I/O channels. Only the analogue I/O modules have 4 channels. Like all systems from the Osorno Automation Team, the PLC modules are only exposed to a 24 V DC control voltage, and are thus completely isolated from the high voltage of field equipment. An array of coupling relays isolate the system for increased operational reliability and safety.

ControLogic™ can adapt to any industrial automation task.

© Osorno Enterprises Inc.